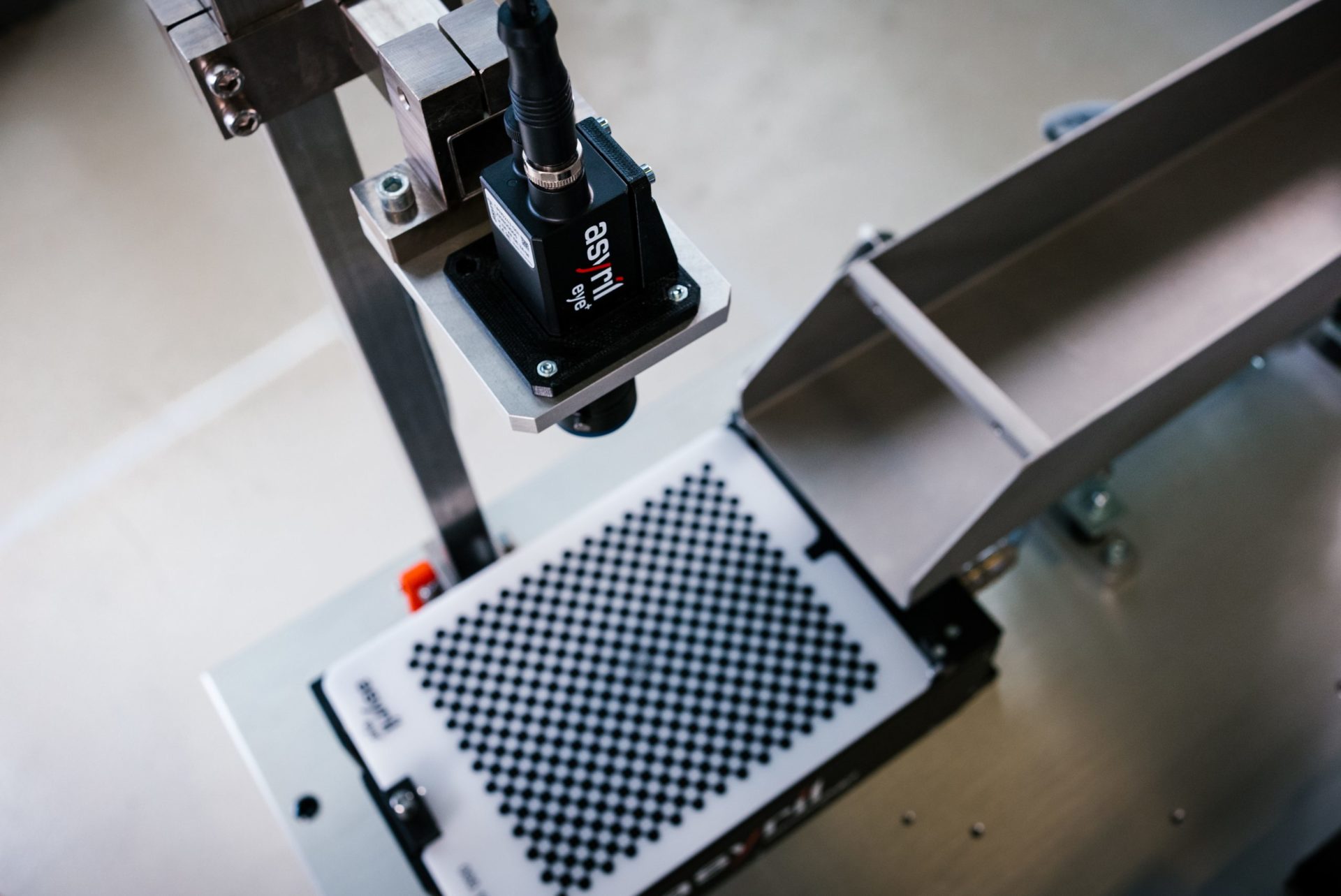

Asyfill smart hopper

Specifically designed for flexible feeding

Revolutionizing part feeding, the Asyfill smart hopper completes Asyril’s intelligent solution. The combination of Asycube feeder, EYE+ smart control system and Asyfill ensures a high-performance flexible feeding process. Integrating Asyfill is very simple, and the parameters are set at recipe level on EYE+ Studio or Asycube Studio, so you can change series without any manual intervention on the hopper. Its compact and integrated controller reduces hardware, cabling and footprint in your production machine, providing a more efficient and customized solution.