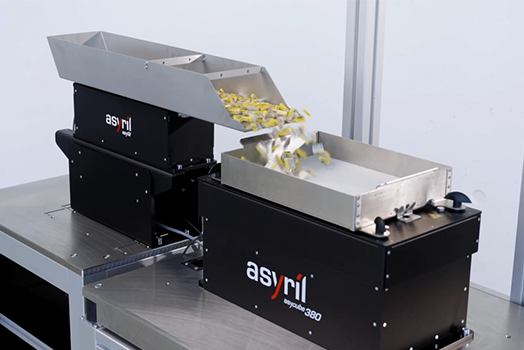

Meet the Asycube Clean 230

The future of hygienic part feeding in pharma.

Designed specifically for cleanroom and pharmaceutical environments, the Asycube Clean 230 is the first flexible feeder engineered to meet the strictest GMP Annex 1 requirements. Compact enough to fit into a 190 Rapid Transfer Port (RTP), its sterilizable plate and chemical-resistant design enable seamless integration into robotized isolators and aseptic zones.

Unlike traditional bowl feeders, the Asycube Clean 230 offers unmatched flexibility: no custom tooling, faster changeovers, and full adaptability for small batches and personalized healthcare.

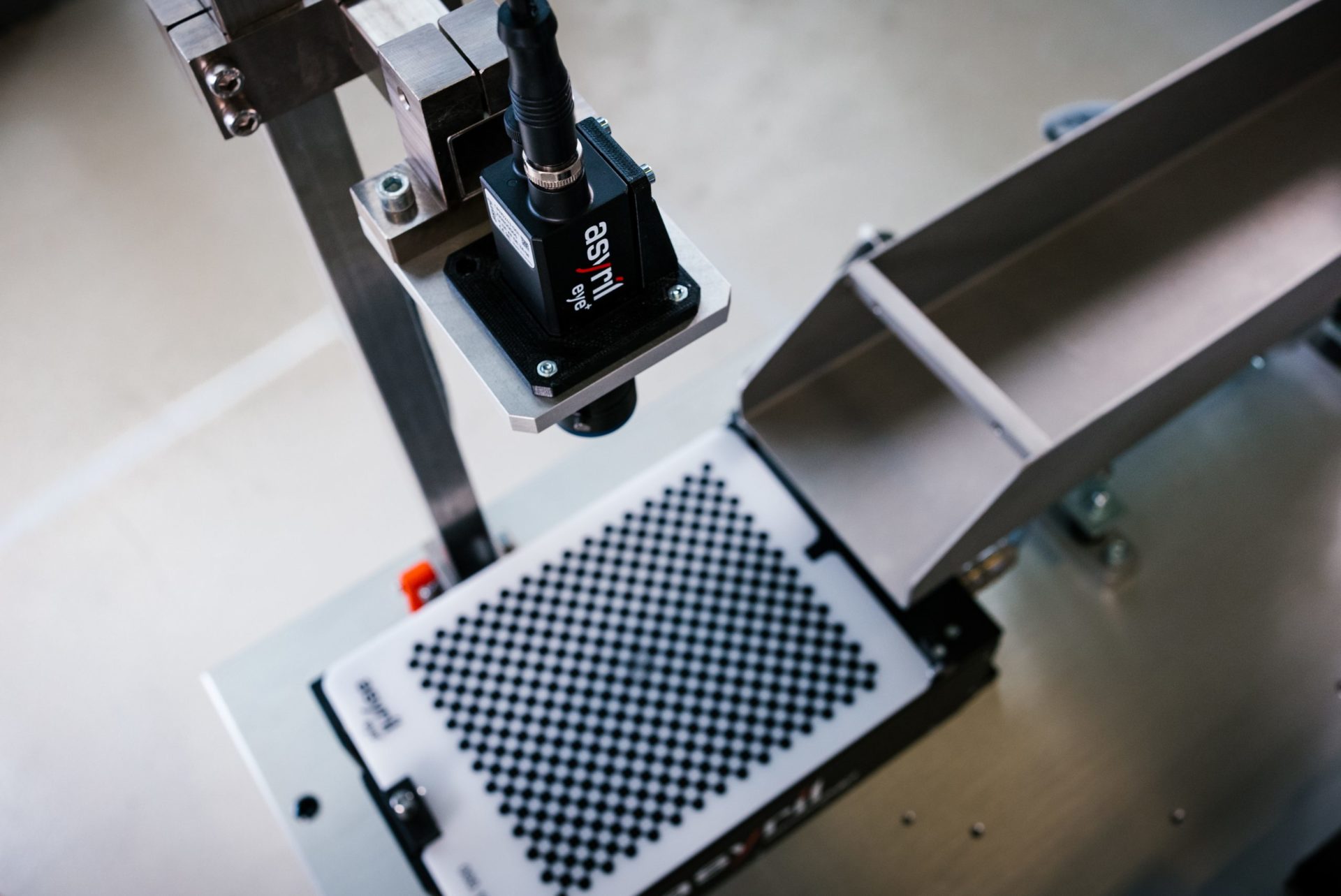

The Asycube Clean 230, like our other products, also features Asyril’s patented 3-axis vibration technology and works seamlessly with the EYE+ smart control system, ensuring fast and accurate part detection.

Built for robots, ready for the future! It’s the smarter, safer choice for modern pharmaceutical production.