Flexibility

A solution for efficient feeding today that will also meet your future needs by its ease and speed of feeding new parts.

A solution for efficient feeding today that will also meet your future needs by its ease and speed of feeding new parts.

Our smart control system allows for easy setup and operation without any prior knowledge of machine vision, including quickly integrating with any type of robot.

Optimized distribution of parts on the platform thanks to 3-axis vibration, which allows parts to be oriented on smooth, structured, grooved or perforated platforms, without having parts accumulate in corners.

A solution for efficient feeding today that will also meet your future needs by its ease and speed of feeding new parts.

Our smart control system allows for easy setup and operation without any prior knowledge of machine vision, including quickly integrating with any type of robot.

Optimized distribution of parts on the platform thanks to 3-axis vibration, which allows parts to be oriented on smooth, structured, grooved or perforated platforms, without having parts accumulate in corners.

Enjoy 3 years of free warranty on your Asycube and stay informed about the latest updates on your product! Take a few minutes to register your Asycube and benefit from an additional 24 months warranty extension, bringing the total warranty period of your product to 36 months.

Asyril develops and produces in Switzerland high performance flexible feeding systems for parts and components from 0.1 to 150 mm in size.

Our patented 3-axis vibration technology and smart control system EYE+ can be easily integrated into your automation machines, increasing flexibility, speed and precision of your feeding process.

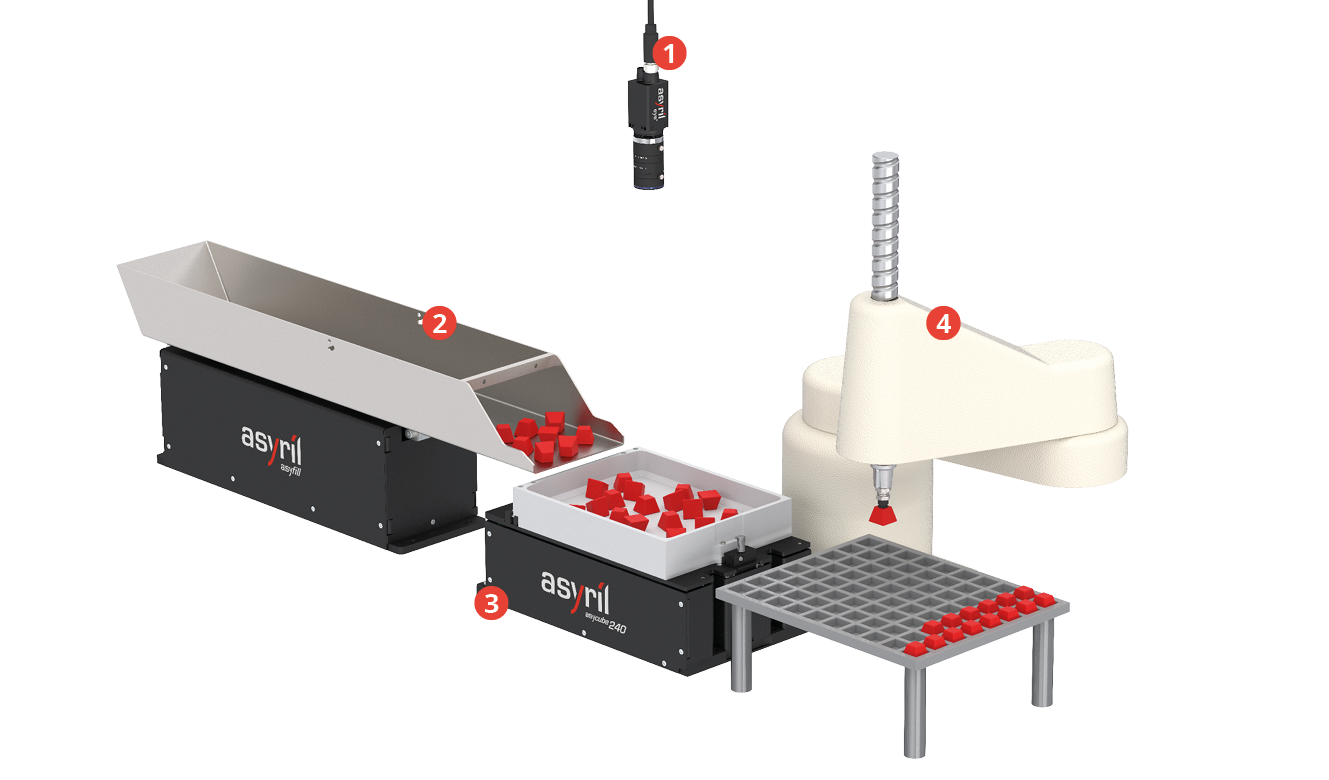

Our flexible feeding system consist of an Asycube, a flexible feeder, and EYE+, a smart control system. The Asycube’s gentle and precise vibrations separate and orientate bulk parts for robot picking. The EYE+ smart control system locates the parts using vision and transmits pick coordinates to the robot. It also manages the hopper and Asycube by performing the most efficient vibration sequences for optimal distribution of parts on the platform as well as managing their location and orientation.

Asyril flexible feeding system

Sites, spread over 3 continents

Distributors who sell our products

Countries where we are present